Printing UV: Transforming the Printing Industry with Innovative Technologies

Printing UV is no longer just a buzzword in the printing industry; it has emerged as a revolutionary technology that is changing the way businesses approach printing. At Boston Industrial Solutions, we pride ourselves on being at the forefront of these advancements, offering a comprehensive range of printing services that utilize the latest in UV technology. This article explores the many facets of printing UV, including its benefits, applications, and why it is a game-changer for businesses looking to enhance their branding and marketing efforts.

What is UV Printing?

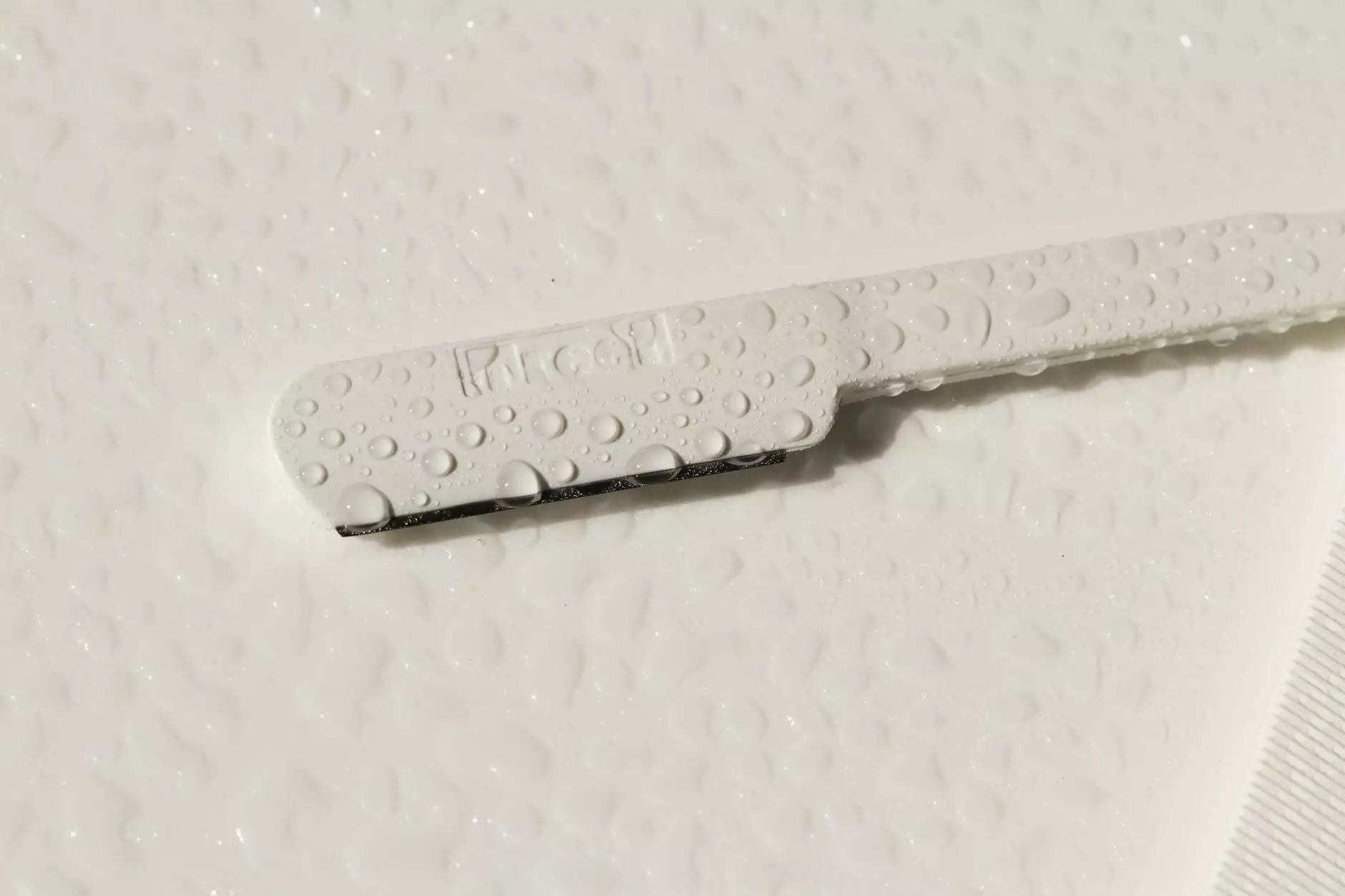

UV printing, or ultraviolet printing, is a technology that employs ultraviolet light to cure or dry the ink as it is printed. Unlike traditional printing methods that rely on solvent-based inks, UV printing uses inks that are photoinitiated, meaning they harden quickly when exposed to UV light. This unique process offers numerous advantages over conventional printing techniques.

How Does UV Printing Work?

The process of printing UV involves several key steps:

- Ink Application: The UV inks are applied on the substrate using a traditional printing press.

- UV Exposure: As the ink is printed, it immediately passes under a UV light source that triggers the curing process.

- Curing: The ink dries instantly, creating a vibrant, durable print that adheres well to various surfaces.

Benefits of Printing UV

Understanding the numerous benefits of printing UV can illuminate why it is swiftly becoming the preferred choice for businesses across different industries. Here are some of the key advantages:

1. Superior Print Quality

One of the standout features of printing UV is its ability to produce outstanding print quality. The inks create vivid colors and sharp images that can withstand the test of time. Unlike traditional inks that can bleed or fade over time, UV-printed images maintain their integrity.

2. Quick Turnaround Times

The instantaneous curing of UV inks significantly reduces the drying time, allowing for quicker completion of printing jobs. This speed enables businesses to meet tight deadlines and fulfill urgent requests without compromising quality.

3. Versatility of Substrates

Printing UV can be performed on a wide range of materials, including:

- Paper and cardstock

- Metal

- Plastic

- Wood

- Glass

- Fabric

This versatility allows businesses to explore various creative options in their marketing materials, packaging, and promotional items.

4. Eco-Friendly Solution

Given today’s emphasis on sustainability, UV printing presents an eco-friendly alternative. The inks used in this process emit fewer volatile organic compounds (VOCs) compared to traditional inks, making it a more environmentally conscious choice.

5. Durability and Longevity

Another important benefit of printing UV is the durability of the prints. The cured inks resist scratches, fading, and moisture, making them ideal for both indoor and outdoor applications. This longevity ensures that printed materials remain vibrant and visible for a more extended period.

Applications of UV Printing

UV printing is applicable across a myriad of industries and sectors. Here are some prominent applications:

1. Marketing Materials

From brochures, flyers, and business cards to banners and posters, printing UV is an excellent choice for creating impactful marketing materials that demand attention.

2. Packaging Solutions

Brands looking to stand out on shelves can employ UV printing for packaging. The vibrant colors and unique finishes can make products more appealing to consumers.

3. Signage

Outdoor and indoor signage benefits greatly from UV printing due to its durability and weather resistance. Signs can be produced in various sizes and shapes, enhancing visibility and branding opportunities.

4. Custom Products

Businesses can create customized items such as promotional gifts, personalized gifts, and even industrial products using UV printing techniques. This customization can enhance brand loyalty and customer engagement.